Despite the great global significance of porcelain tile manufacture, the scientific activity in porcelain tile’s almost 30-year existence does not match the importance of the business. Although scientific output has been scarce, technological advances have been and still are spectacular, largely driven by machinery builders, in collaboration with glaze and pigment producers.

This paper begins by describing the evolution and distribution of research into porcelain tile per country. The study then reviews the major scientific and technological advances, focusing principally on the developments in raw materials compositions resulting from the introduction of certain key raw materials to enhance composition quality. As the interpretation of unfired body microstructure, and the relation of unfired tile microstructure to processability and to sintered tile microstructure and properties have drawn particular attention from the scientific community, the paper addresses these issues in depth.

The last part reviews the R&D lines which, in the authors’ view, will witness further development in the short and medium term and which obviously parallel the technology advances in the product and the manufacturing process.

Introduction

Within the great range of products marketed by the ceramic industry, the developments in porcelain tile have been quite outstanding. Porcelain tile emerged (in its current form) in the late 1970s in Italy [1] as a technical high performer, characterised by a natural look, and more similar in appearance to natural rock or stone than any other ceramic product.

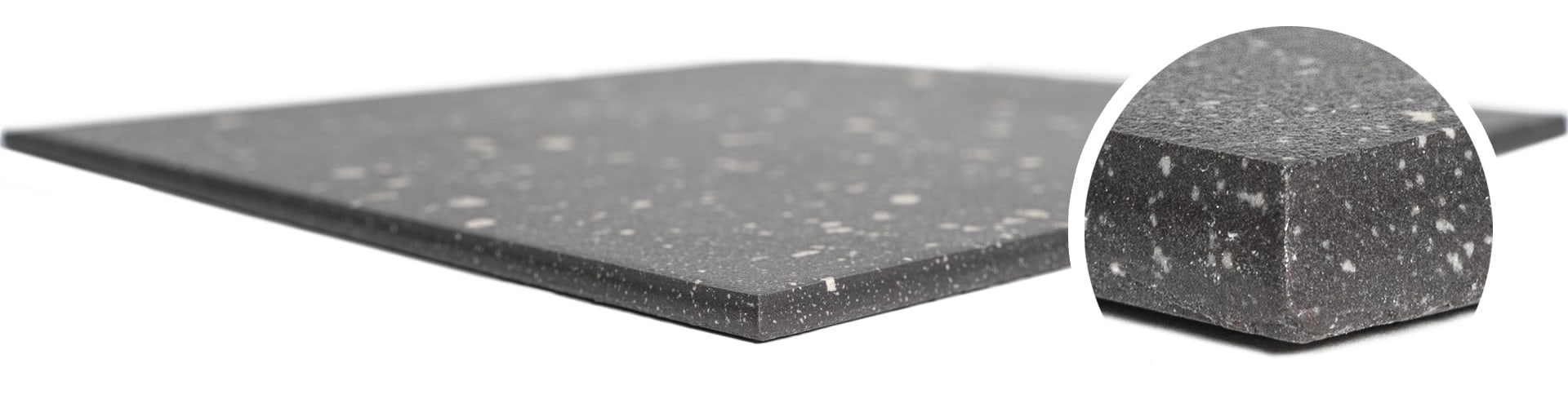

Porcelain tile is a very compact product, vitrified throughout and with extremely low porosity. This low porosity is an essential feature, which provides the material with excellent mechanical and chemical properties, making it frost resistant and therefore extremely serviceable for outdoor flooring and wall cladding in cold climates. It is also highly resistant to chemical substances and cleaning agents. It resists abrasion well and has a high breakage threshold, making it ideal for highly trafficked and industrial areas, in addition to being easy-to-clean and thus perfect for paving areas where hygiene is of prime importance.

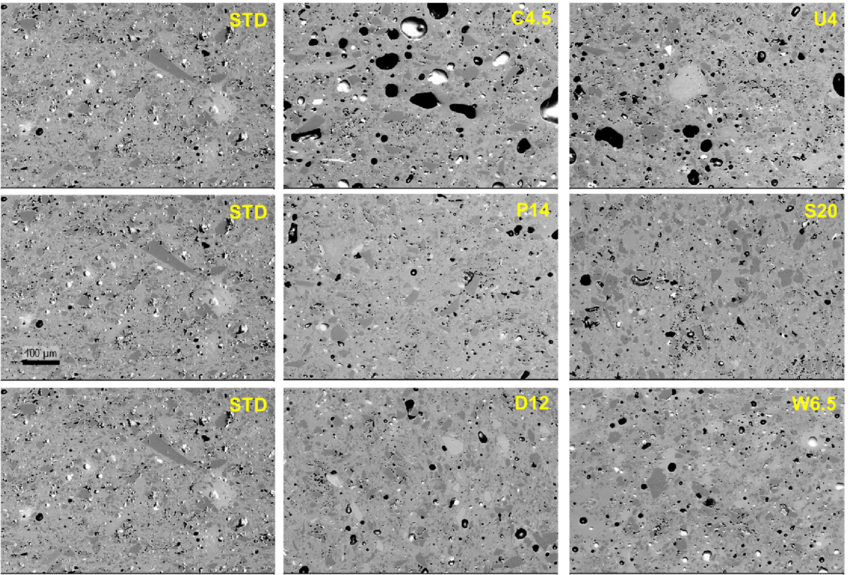

The starting composition is made from a triaxial mixture of clay or kaolin, quartz, and feldspar. The clay fraction helps forming by providing plasticity and dry mechanical strength during processing, and develops mullite and glassy phase during firing. Feldspars develop glassy phase at low temperatures (sodium feldspar being mainly used), assisting the sintering process, and enabling virtually zero (<0.5%) open porosity and a low level of closed porosity (<10%) to be achieved. Quartz promotes thermal and dimensional stability thanks to its high melting point .

The industrial processing of porcelain tile includes three main stages: (1) wet milling and homogenisation of raw materials, followed by spray-drying of the resulting suspension; (2) uniaxial pressing at 35–۴۵ MPa of the spray-dried powder with a moisture content of 5–۷%; (۳) fast firing for 40–۶۰ min at 1180–۱۲۲۰ °C to obtain maximum densification.

The search for a new aesthetics has given rise to a broad spectrum of end product finishes, such as polishing. Two common types of porcelain tile finishes are the so-called ‘natural’ (i.e. as-fired, unpolished) and polished porcelain tile. Natural porcelain tile undergoes no treatment after firing; its appearance is natural, and closely resembles that of rocks or stones found in nature, such as slate, marble, or granite. The polished finish is obtained by grinding and polishing after firing, in order to provide the product with a high-gloss finish like that of polished marble or granite. Porcelain tile is further often machined in order to rectify and square, and/or chamfer the tiles; this is done to enable tile installation with a minimum grout joint, which yields a highly aesthetic finish.

Another kind of product that has made great inroads into the international market in the last 8 years is glazed porcelain tile. Used especially because of its frost resistance and low porosity, the product has become an alternative to other glazed ceramic products and represents yet another opportunity for manufacturers that have so far made unglazed porcelain tiles.

The paper reviews the major scientific and technological advances, focusing particularly on the developments in raw materials compositions, with the introduction of certain key raw materials to enhance composition quality. Moreover, the interpretation of unfired body microstructure, and the relation of unfired tile microstructure to processability and to sintered tile microstructure and properties have drawn particular attention from the scientific community. The latter part of the work reviews the R&D lines which, in the authors’ view, will witness further development in the short and medium term and which obviously parallel the technology advances in the product and the manufacturing process.

Section snippets

Scientific production in porcelain tile’s almost 30-year existence

A simple analysis of the scientific production on porcelain tile in the last 30 years leads to a modest outcome. Only 131 research papers on either the porcelain tile manufacturing process or porcelain tile materials are to be found in the ‘World of Science’ journals up to 2008. This means that fewer than five papers are published per year on porcelain tile worldwide. The number of patents for the same period is also scant, about 120 documents being available through Matheo patents software.

The…

Major scientific advances

This section addresses some of the major scientific and technological developments in porcelain tile in its almost 30-year existence. The knowledge involved has been expressed in different scientific and technological papers. However, in many cases, it has only been reflected at industry level or presented exclusively at fairs or exhibitions. The authors are aware of the limited length of this paper, and the difficulty of translating the myriad developments undergone by porcelain tile in this

Future research lines

This last part of the paper reviews the R&D lines which, in the opinion of the authors, will witness further development in the short and medium term, development that will obviously parallel the technological advances of the product and its manufacturing process. For the sake of simplicity, these lines will be divided into the following three categories: new materials and compositions, novel functionalities and applications, and advanced technologies in the manufacturing process.

Acknowledgements

The paper has sought to set out part of the experience gathered in the last years by technical staff at ITC in the field of porcelain tile. I should therefore like to express my gratitude to all the people at ITC who have participated direct or indirectly in these studies, as well as to the companies, and State and Regional organisations whose economic support has made the research possible.

I would particularly like to thank the people who, with their comments, discussions and suggestions, have

نظرات ۰