Beyond Flatness – The Dawn of the Tactile Tile

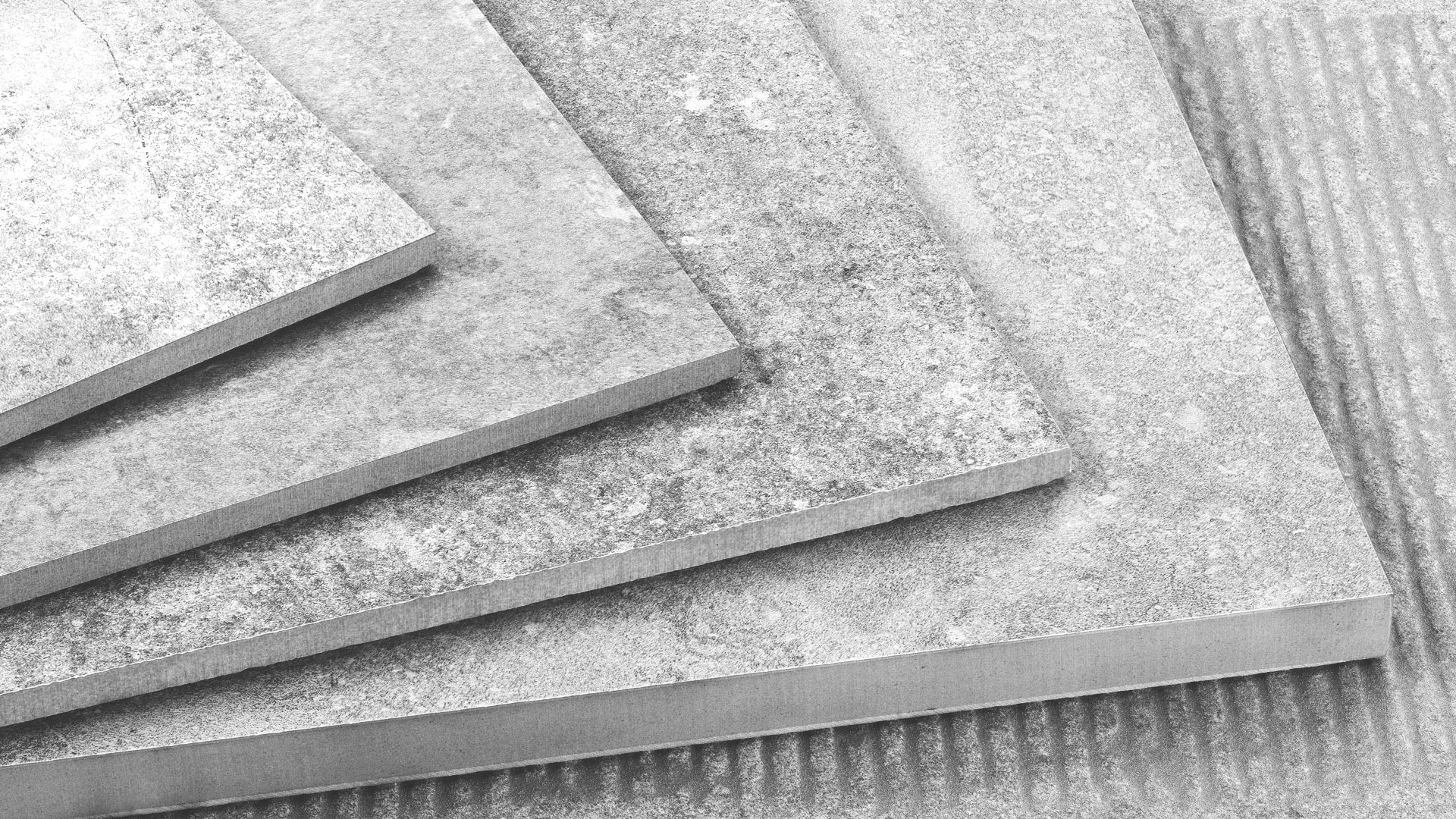

For decades, the choice of a ceramic or porcelain tile largely centered on color, pattern, and size. The surface, though functional, often remained a secondary consideration—either uniformly glossy or consistently matte. That era is over. Today, the surface of a tile is no longer a passive coating; it is the primary design element, a sensory experience that engages both sight and touch. We are witnessing the New Surface Alchemy—a technological and artistic revolution driven by advanced glazes and digital texturing.

The shift is profound: architects and interior designers are moving beyond flatness to embrace finishes that are metallic, super-reflective, deeply matte, or strikingly three-dimensional (3D). This comprehensive article is a deep dive into the practical, chemical, and digital innovations driving this trend. We’ll explore the cutting-edge glaze technologies that create these effects, the surface innovation techniques that transform a simple tile into a piece of art, and the commercial advantages for brands that embrace the ۳D experience. Prepare to decode the science and artistry behind the most sought-after tile surface innovation trends in the modern construction and design industry.

Part 1: The Glaze Revolution – Chemistry Meets Artistry

The foundation of any tile surface effect is the glaze. Traditionally a mixture of glass-forming materials (frits), fluxes, and coloring oxides, the modern glaze is a highly engineered compound designed for both aesthetic impact and superior performance.

The Rise of Super-Performance Glazes

Modern manufacturing demands glazes that not only look spectacular but also withstand extreme conditions. This has led to the development of several high-performance categories:

۱. Super-Gloss (Full Polished) Glazes

The pursuit of high reflectivity has pushed manufacturers toward super-gloss glazes that offer a mirror-like finish superior to standard polished porcelain.

- Mechanism: These glazes utilize high concentrations of crystalline materials and specific firing cycles to achieve maximum transparency and a high refractive index. The surface is often finished with a Lappato (semi-polished) or Full Polished treatment after firing, which physically enhances the luster.

- Aesthetic & Application: Ideal for visually expanding smaller spaces, maximizing natural light, and creating an undeniable sense of luxury. They are frequently used in commercial lobbies, high-end residential floors, and luxury bath environments.

- Key Advantage: Enhanced visual depth and color vibrancy compared to unglazed polished porcelain.

۲. Ultra-Matte and Deep Matte Glazes

At the opposite end of the spectrum, the demand for sophisticated, low-sheen surfaces has fueled innovation in matte finishes.

- Mechanism: Deep matte glazes achieve their effect through controlled micro-crystallization within the glaze layer during firing. The presence of these micro-crystals diffuses light, preventing reflection. New additives also enhance the “soft-touch” quality, creating a velvet-like tactile experience.

- Aesthetic & Application: Perfect for creating warm, cozy, and minimalist environments. They hide imperfections and reduce glare, making them highly popular for large-format slabs in open-plan living areas and professional workspaces.

- SEO Term Focus: Matte-finish tiles, low-glare ceramic, soft-touch tile surfaces.

۳. Metallic and Reactive Glazes

These are perhaps the most visually dramatic innovations, moving tiles away from stone or wood imitation toward completely unique, artistic looks.

- Metallic Glazes: Glazes incorporating metal compounds (like copper, iron, or zinc) that, when fired, create a shimmering, oxidized, or aged metal appearance. These can range from subtle brass effects to dramatic, heavily patinated finishes.

- Reactive/Lustre Glazes: These glazes are designed to be chemically unstable during firing. The result is an unpredictable, unique color variation or “pooling” of the glaze that mimics a handcrafted, artistic process. This technique ensures that virtually no two tiles are exactly alike, fulfilling the market demand for uniqueness and artisanal flair.

- Brand Relevance: Brands like Emilgroup, often pioneers, leverage these glazes to create collections that appear to be forged metal or aged concrete.

Part 2: Surface Innovation – The Digital and Mechanical Leap

While glaze chemistry dictates the color and shine, mechanical and digital technologies are responsible for the texture and three-dimensional effects. This is where the concept of the “uniform surface” is entirely shattered.

Digital Decoration and Inkjet Technology (DGT)

The single most significant breakthrough enabling ۳D tile experience is the evolution of Digital Glazing Technology (DGT).

۱. Digital Structured Glazing (DSG)

- Process: Unlike standard decorative inkjet printing, DSG uses specialized inkjet heads to jet high-viscosity, transparent, or opaque glazes onto the tile surface before the final firing. These glazes are formulated to be thicker and have a higher surface tension.

- The Result: By controlling the amount of material deposited, manufacturers can create precise, raised profiles that are perfectly synchronized with the underlying graphic pattern. For instance, a wood-effect tile can have raised surface effects following the wood grain, while a marble tile can have glossy, slightly elevated “veins” perfectly aligning with the digitally printed stone pattern.

- User Benefit: This achieves the look and feel (haptic fidelity) of a natural material with superior durability and repeatability.

۲. Dry Granule Application (Dry Decoration)

- Process: Post-digital printing and prior to firing, specialized machines precisely deposit dry ceramic granules (frits or crystalline powder) onto specific areas of the wet glaze surface. The size, type, and distribution of these granules are digitally controlled.

- The Result: During firing, these granules melt and fuse, creating deep, intricate, and often highly resilient textures. This technique is crucial for manufacturing anti-slip or structured outdoor tiles that still maintain an aesthetic finish.

- SEO Term Focus: Anti-slip textured tiles, structured outdoor porcelain, ceramic surface texture.

The 3D Experience: Embossed and Relief Tiles

The combination of digital glazing and dry decoration is key to the trend of ۳D tiles or Embossed Tiles. This is where the surface truly becomes an artwork, moving beyond imitation to creation.

- Tactile Impact: The goal is to create a tactile surface that users instinctively want to touch. This includes geometric reliefs, wave patterns, basket-weave textures, or even subtle, fabric-like finishes.

- Light and Shadow Play: Embossed effects play dramatically with light. The interplay of highlights on the raised areas and shadows in the recesses creates a dynamic, ever-changing visual impact that a flat tile cannot replicate.

- The Emilgroup Example: As highlighted in the initial brief, leading brands like Emilgroup have championed this with collections featuring geometric, three-dimensional reliefs. This is not simply decoration; it’s an architectural element that provides volumetric presence to a wall or floor.

- Commercial Insight: These products command a significantly higher price point, positioning the manufacturer as an artistic and innovative brand.

Part 3: Performance and Practicality – The Functional Edge

Beyond aesthetics, tile surface innovation directly addresses critical functional requirements in both residential and commercial projects.

Durability and Wear Resistance (PEI Rating Enhancement)

Advanced glazes are fundamentally enhancing the mechanical properties of the finished tile.

- Glass-Ceramic Glazes: New frits are formulated to partially or fully crystallize into a glass-ceramic structure during the fast-firing process. These crystalline phases (often silicates) are significantly harder than the residual glass matrix.

- Benefit: This creates a much tougher surface that improves the tile’s PEI rating (Porcelain Enamel Institute) for abrasion resistance. For high-traffic commercial spaces, this increased durability is non-negotiable.

- SEO Term Focus: High PEI rating tiles, durable ceramic surfaces, enhanced wear resistance glazes.

Hydrophobicity and Functional Surfaces

The physical structure of the surface, now controllable at a microscopic level, allows for functional performance characteristics.

- Self-Cleaning Surfaces: Some new formulations incorporate photocatalytic materials (like titanium dioxide) into the glaze. When exposed to UV light, these materials break down organic pollutants, leading to a self-cleaning effect for exterior facade slabs.

- Antibacterial Glazes: Crucial for healthcare, hospitality, and public restrooms, glazes are increasingly being doped with silver or copper ions. These metallic ions are released slowly, creating an environment that significantly inhibits the growth of bacteria and certain viruses, maintaining a high level of hygiene.

- Practical Application: These functional surfaces provide a critical advantage in highly specified projects, positioning the tile not just as a covering but as an active component of the building’s maintenance and health strategy.

Part 4: Commercial Strategy – Becoming an Artistic Brand

For manufacturers, investing in glaze technology and surface innovation is a powerful marketing and commercial strategy. It shifts the company’s position from a commodity producer to a design leader.

۱. Elevated Perceived Value

A flat, standard matte tile is often judged purely on price. A tile featuring a super-gloss finish, a synchronized 3D texture, and a metallic sheen is perceived as a specialized, luxury, and artistic product.

- Pricing Power: This higher perceived value justifies a premium price point, improving profit margins dramatically. The cost of the innovative glazes and digital machinery is an investment that pays off through higher selling prices.

۲. Creating “Signature Looks”

Innovative surfaces allow brands to establish signature, instantly recognizable collections that cannot be easily copied by competitors using standard technology.

- Uniqueness Factor: The complex interplay between a custom-developed reactive glaze and a proprietary digital structure creates a unique product DNA. For instance, the specific metallic sheen of one company’s glaze can become their aesthetic trademark.

- Designer Loyalty: Architects and designers are constantly seeking unique materials for their projects. By offering these distinctive surface effects, manufacturers cultivate loyalty among the design community.

۳. Sustainability Through Efficiency

Digital glazing is not only a tool for aesthetics but also a significant step toward manufacturing efficiency and sustainability.

- Reduced Waste: Precise inkjet application of glazes reduces material consumption compared to traditional bell or waterfall glazing methods, leading to less waste and material usage.

- Optimization: The ability to print only the required amount of glaze for a specific texture means fewer wasted resources and energy, aligning with the growing global demand for environmentally conscious building materials.

Conclusion: The Future is Textured, Reflective, and Tactile

The ceramic and porcelain tile industry stands at the crest of a massive wave of innovation, where the surface itself has become the central canvas for design. The future is decisively moving beyond flatness.

This revolution is driven by the synergistic power of chemistry and digital technology: advanced frits creating deep matte and super-gloss finishes, and Digital Structured Glazing (DSG) engineering perfect ۳D textures and embossed effects. For manufacturers, this is more than a trend; it’s a new standard. Embracing this New Surface Alchemy—as demonstrated by industry leaders in their focus on Metallic Glazes, functional surfaces, and the captivating ۳D experience—is the clearest path to elevated brand perception, increased market share, and positioning oneself as a true artistic and technological pioneer in the global construction materials sector. The tile is no longer just a functional element; it is now an indispensable, tactile piece of architectural art.

نظرات ۰