Imagine working in an environment where acids, alkalis, and harsh chemicals are part of the daily routine. The floors, walls, and surfaces around you face a constant threat of erosion and damage. In such places—like chemical plants, laboratories, or food processing units—ordinary materials simply won’t survive. That’s where acid-resistant tiles come in, acting as a powerful shield against chemical corrosion. These tiles aren’t just another building material; they’re a smart solution designed to protect, endure, and perform where others fail. In this article, we’ll explore everything you need to know about acid-resistant tiles: what they are, how they work, their benefits, and why they’re a must-have in certain industries. With about 3,500 words of detailed insights, this guide is perfect for architects, engineers, facility managers, or anyone curious about cutting-edge construction materials. Let’s dive into the world of acid-resistant tiles and discover why they’re revolutionizing industrial spaces.

What Are Acid-Resistant Tiles?

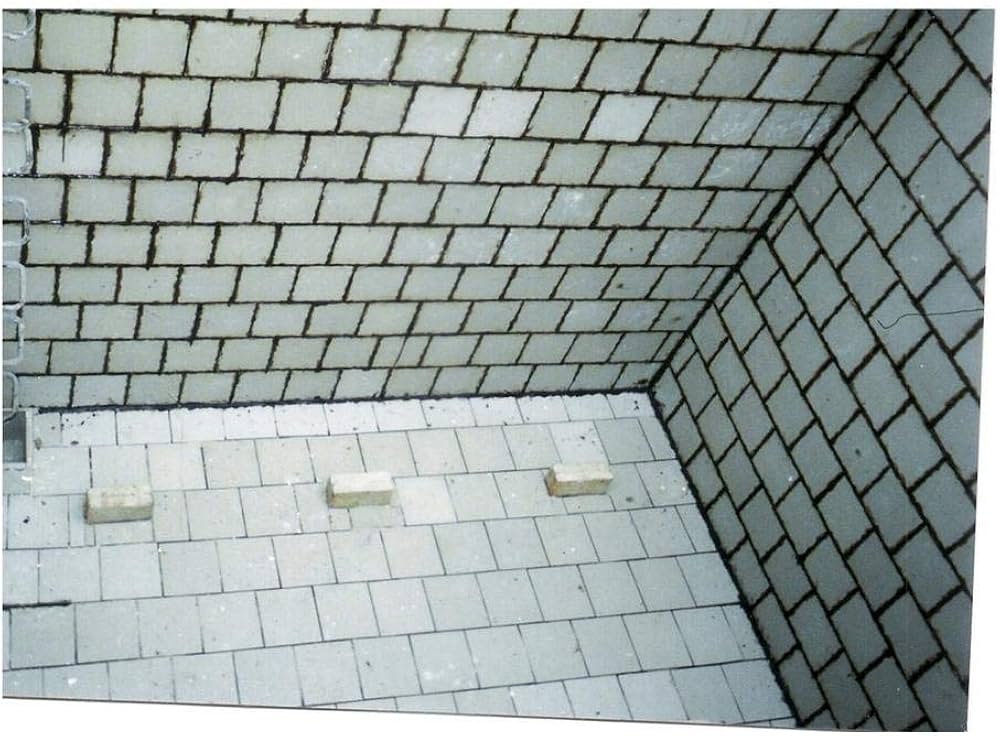

Acid-resistant tiles are specially crafted ceramic or porcelain tiles built to resist damage from chemicals like acids, alkalis, and solvents. Unlike regular tiles that might crack, stain, or wear down when exposed to corrosive substances, these tiles stay strong and intact. They’re made from premium materials like clay, feldspar, and minerals, which are fired at super-high temperatures (often over 1200°C) to create a tough, non-porous surface. This process ensures chemicals can’t seep in and cause harm, making them ideal for harsh environments.

The Science Behind Their Strength

So, what makes these tiles so tough? It’s all about their structure. When fired at extreme heat, the materials bond tightly, leaving almost no tiny gaps or pores. This low porosity stops liquids—especially corrosive ones—from soaking into the tile. Some versions even come with a special glaze, a protective layer that’s chemically inert (meaning it doesn’t react with acids or other substances). Together, the dense core and inert surface create a barrier that laughs in the face of chemical attacks.

Types of Acid-Resistant Tiles

Not all acid-resistant tiles are the same. Here’s a rundown of the main types you’ll find:

- Ceramic Acid-Resistant Tiles: The go-to choice for most industries, these offer solid protection against a variety of chemicals. They’re affordable and reliable for general use.

- Porcelain Acid-Resistant Tiles: Stronger and less absorbent than ceramic, porcelain tiles are great for heavy-duty areas with lots of foot traffic or tough conditions.

- Vitrified Acid-Resistant Tiles: These are superstars—vitrified means they’re almost completely waterproof and ultra-dense, perfect for constant exposure to strong acids.

- Epoxy-Coated Tiles: These aren’t traditional tiles but surfaces treated with epoxy for chemical resistance. They work well but might not last as long as fired tiles.

Benefits of Acid-Resistant Tiles

Why choose acid-resistant tiles over regular options? Their advantages go way beyond just handling chemicals. Let’s break it down:

Super Tough and Long-Lasting

These tiles are built to take a beating. Their dense makeup resists both chemical damage and physical wear, like scratches or heavy loads. That means they last for years—sometimes decades—saving you from constant repairs or replacements. In busy industrial settings, this durability keeps operations running smoothly.

Safe and Clean

Spills happen, especially in places dealing with chemicals. Acid-resistant tiles don’t soak up those spills, making cleanup a breeze and keeping dangerous substances from lingering. This is a huge plus in industries like food production or pharmaceuticals, where hygiene is non-negotiable. A cleaner, safer workspace? Yes, please!

Saves Money in the Long Run

Sure, acid-resistant tiles might cost more upfront than standard tiles. But think long-term: fewer repairs, less maintenance, and no need to replace them often. Plus, they protect the structures underneath from costly damage. Over time, that adds up to big savings.

Looks Good Too

Who says industrial can’t be stylish? Today’s acid-resistant tiles come in all sorts of colors, textures, and finishes. You can keep your space safe and functional while making it look sharp and professional—perfect for labs, factories, or anywhere appearances matter.

Where Are Acid-Resistant Tiles Used?

These tiles shine in all kinds of tough environments. Here are some top spots where they’re making a difference:

Chemical Plants

In chemical plants, acids and solvents are everywhere. Acid-resistant tiles line floors, walls, and containment zones to stop corrosion in its tracks. They also prevent leaks from reaching the ground, protecting the environment and the facility itself.

Laboratories

From school labs to high-tech research centers, spills are a risk. These tiles keep surfaces intact and safe, whether it’s a small acid splash or a bigger mess. They’re a must for lab floors and countertops.

Food and Beverage Factories

Think about citrus processing or dairy plants—acidic ingredients and cleaning chemicals are common. Acid-resistant tiles handle it all, keeping floors clean and meeting strict health standards with their easy-to-wipe surfaces.

Pharmaceutical Facilities

Making medicines often involves strong chemicals, and cleanliness is critical. These tiles resist corrosion while supporting sterile conditions, making them ideal for cleanrooms and production areas.

Wastewater Treatment

Treating wastewater means dealing with a mix of chemicals and waste. Acid-resistant tiles protect tanks, channels, and floors, ensuring the system lasts longer and works better.

How to Install and Maintain Acid-Resistant Tiles

To get the most out of these tiles, you need to install and care for them the right way. Here’s how:

Installation Tips

- Prep the Surface: Make sure the area is clean, dry, and smooth. Fix any cracks or bumps first.

- Pick the Right Adhesive: Use acid-resistant glue, like epoxy-based ones, to hold up in chemical settings.

- Grout Smart: Go for acid-resistant grout so the gaps between tiles stay just as tough as the tiles themselves.

- Hire Pros: This isn’t a DIY job—experts know how to handle these special tiles for the best results.

Maintenance Made Easy

- Clean Regularly: Use gentle, pH-neutral cleaners to keep the surface happy. Skip harsh scrubbers that might scratch.

- Wipe Spills Fast: Even though the tiles can handle chemicals, clean up spills quickly to avoid any unnecessary stress.

- Check Up: Look for cracks or loose spots now and then. Fix them fast to keep everything solid.

Choosing the Best Acid-Resistant Tiles

Not sure which tiles to pick? Here’s what to think about:

Match the Chemicals

Know what chemicals you’re dealing with—some tiles handle certain acids or alkalis better than others. Check ratings to be sure.

Handle the Load

Heavy machines or lots of people walking around? Go for stronger options like porcelain or vitrified tiles that can take the pressure.

Keep It Stylish

Function matters most, but looks count too. Pick a design that fits your space, especially in visible areas.

Watch the Budget

Higher quality might cost more now but pays off later. Weigh the upfront price against the long-term value.

Real-Life Examples of Acid-Resistant Tiles

Need proof they work? Check out these stories:

Chemical Plant Success

A plant in Germany swapped out failing concrete floors for ceramic acid-resistant tiles. After five years, they cut maintenance costs by 70% and had no floor issues—plus, the slip-resistant surface boosted safety.

Pharma Cleanroom Win

An Indian drug maker upgraded to vitrified tiles in their cleanroom. Cleaning time dropped by 30%, contamination risks fell, and they stayed compliant with tough regulations—all thanks to the tiles.

The Future of Acid-Resistant Tiles

The need for these tiles is only growing as industries get stricter about safety and sustainability. New tech is making them even better—think tiles with germ-killing surfaces or ones that handle heat too. Plus, eco-friendly production, like using recycled materials, is on the rise. Acid-resistant tiles aren’t just keeping up—they’re leading the way.

Conclusion

Acid-resistant tiles are more than a practical choice; they’re a lifeline for industries facing chemical challenges. With their unbeatable strength, safety features, and versatility, they protect spaces where ordinary materials would crumble. Whether you’re designing a lab, running a factory, or managing a treatment plant, these tiles offer peace of mind and performance that lasts. By understanding how they’re made, their benefits, and how to use them right, you’re ready to make smart choices for your projects. As technology keeps improving, acid-resistant tiles will stay at the forefront, defending against corrosion and shaping the future of tough, reliable infrastructure.

نظرات ۰