In the heart of Iran’s industrial desert, specifically within the bustling tile clusters of Yazd and Meybod, a silent revolution has taken place over the last decade. Imagine a factory floor twenty years ago: massive screen-printing machines, heavy frames, and days of downtime just to change a single floral pattern. Today, that same space is occupied by sleek, high-speed digital printers that can switch designs with a click of a button. But is digital printing just a “cool” technological upgrade, or is it the ultimate engine for profitability?

For factory owners and production managers, the transition to Digital Tile Printing is no longer a luxury—it is a survival mechanism. As global competition stiffens and consumer demands for high-definition, stone-mimicking textures rise, understanding the technical and financial nuances of digital inkjet technology is paramount. This article serves as a comprehensive roadmap for maximizing your factory’s ROI through digital integration, covering everything from initial CAPEX to the hidden costs of ink management, specifically tailored for the competitive landscape of the ceramic industry.

۱. Understanding the Core: What is Digital Ceramic Tile Printing?

At its simplest level, Digital Tile Printing is an “inkjet” process, similar to the printer in your office but scaled to industrial proportions and using specialized inorganic inks. Unlike traditional rotocolor or screen printing, which requires physical contact and pre-made templates, digital printing is a non-contact process.

The Technology Behind the Magic

Digital printers use piezoelectric printheads. These heads contain thousands of microscopic nozzles that “fire” droplets of ink onto the tile surface as it moves along the conveyor belt. Because there is no contact, the risk of tile breakage is significantly reduced, and patterns can be printed edge-to-edge.

-

Inks: These are not standard dyes. They are suspensions of metallic oxides and pigments in a solvent or oil-based carrier. When fired in the kiln at temperatures exceeding $۱۱۰۰^\circ\text{C}$, these inks fuse with the glaze to create a permanent, durable finish.

-

The “Drop-on-Demand” System: The printer only releases ink where it is needed, based on a digital image file (usually a high-resolution TIFF or PSD).

Operational Tip: If you are transitioning from analog, start by auditing your current breakage rate. Digital printing typically reduces “mechanical stress” breakages on the line by up to 15%, providing an immediate boost to your net output.

۲. The Economic Shift: Comparing Analog vs. Digital ROI

To understand why Digital Tile Printing is a game-changer for profitability, we must look at the “hidden costs” of traditional methods.

Comparative Analysis Table

| Feature | Traditional Screen/Rotocolor | Digital Inkjet Printing |

| Setup Time | ۴–۸ hours (Frame/Roller change) | < 5 minutes (Software load) |

| Minimum Run | Thousands of square meters | ۱ square meter |

| Design Detail | Limited by screen mesh | Photo-realistic (360-1000 DPI) |

| Waste | High (Ink left in screens/rollers) | Low (Precise drop placement) |

| Labor | High (Manual cleaning/alignment) | Low (Software-driven) |

Impact on Profitability

In the Iranian market, where energy costs are rising and export markets like Iraq and the CIS countries demand high-quality aesthetics, the ability to produce “Small Batches” is vital. Analog printing forces you to keep massive inventories of unsold tiles because small runs aren’t cost-effective. Digital printing allows for “Just-in-Time” production, slashing your warehouse holding costs by an estimated 20-30%.

۳. Maximizing Factory Profitability: The Three Pillars

A common mistake among factory owners in Yazd or Isfahan is assuming that buying the printer is the end of the journey. In reality, Digital Tile Printing profitability is built on three pillars:

I. Ink Optimization

Ink is the highest recurring cost in digital printing. While the printer itself is a fixed asset, the ink is a variable cost that can eat your margins if not managed.

-

Actionable Strategy: Implement a “Color Management System” (CMS). By calibrating your ICC profiles correctly, you can achieve the same visual depth using 15% less ink. In a high-volume factory producing 10,000 $m^2$ per day, a 15% saving in ink translates to tens of thousands of dollars annually.

II. Machine Uptime and Printhead Health

The printhead is the “heart” of the machine. A single clogged nozzle can ruin a premium tile.

-

Actionable Strategy: Maintain a strict temperature and humidity-controlled environment. Digital printers are sensitive to the dust common in ceramic factories. Enclosing the printer in a pressurized “Clean Room” can extend printhead life by 40%.

III. High-Value Customization

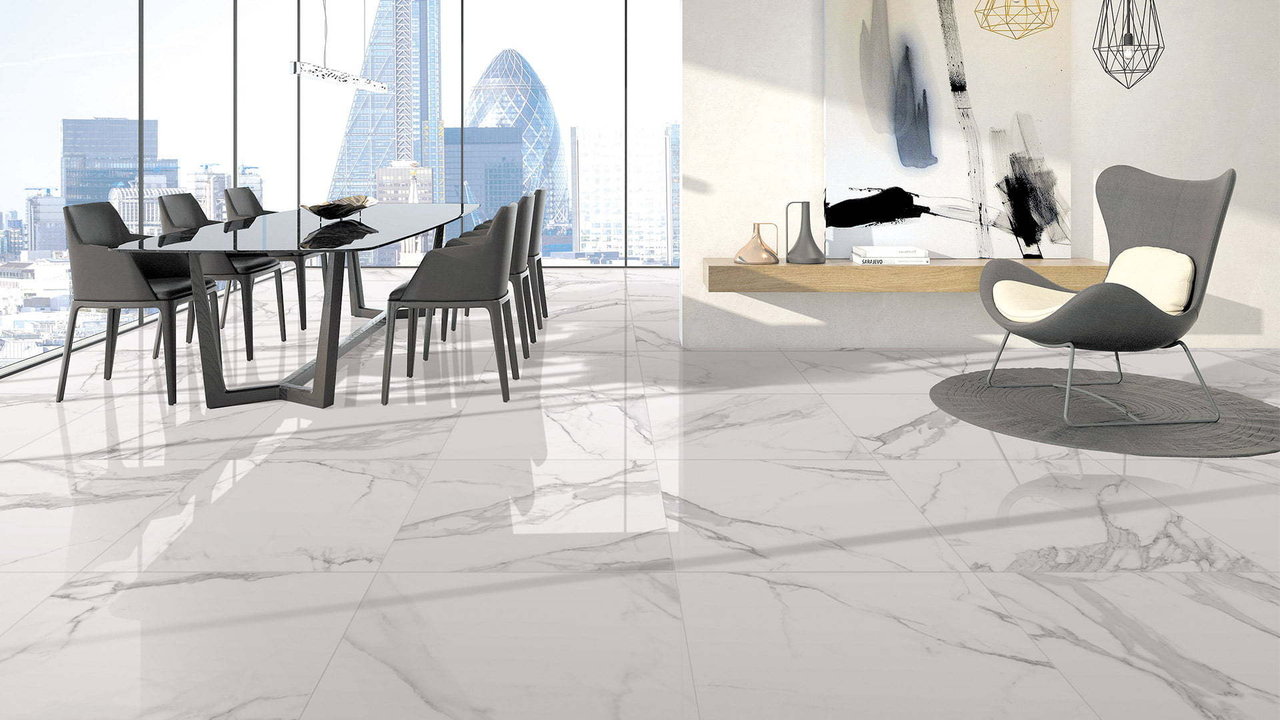

Digital printing allows you to mimic expensive natural materials like Carrara marble, oak wood, or rare granites. These “Digital Effects” sell at a 50-100% markup compared to standard monochromatic tiles.

۴. Operational Implementation Checklist for Factory Managers

Moving to Digital Tile Printing requires a cultural shift in the workforce. Use this checklist to ensure a smooth transition:

-

Infrastructure Audit: Ensure your conveyor system is vibration-free. Vibrations lead to “banding” (visible lines) in the print.

-

Software Training: Invest in training for your design team. They are no longer just “pattern makers”; they are digital colorists.

-

Filtration Systems: Ensure your ink delivery system has high-quality filters. Small particles are the #1 killer of printheads.

-

Kiln Synchronization: Digital inks react differently to heat than traditional glazes. Conduct a “Gradient Test” to find the optimal firing curve for your new digital palette.

Pro Tip: Create a “Digital Maintenance Log” where operators record printhead voltage and temperature every 4 hours. Early detection of voltage spikes can prevent a $2,000 printhead from burning out.

۵. Analyzing the Costs: CAPEX vs. OPEX

While the benefits of Digital Tile Printing are clear, the investment is significant.

Initial Investment (CAPEX)

A high-end industrial digital printer can cost anywhere from $200,000 to over $600,000 depending on the number of bars (colors) and width. However, when calculating ROI, you must include:

-

Stabilized power supplies (UPS).

-

Clean room construction.

-

Staff retraining.

Operating Expenses (OPEX)

The primary OPEX components are:

-

Ink (60-70% of OPEX): Prices fluctuate based on pigment quality.

-

Printhead Replacement: Budget for 10-20% replacement per year.

-

Electricity and Maintenance: Relatively low compared to the mechanical maintenance of rotocolors.

Case Study: A mid-sized factory in Meybod reported that while their initial investment was high, they broke even in just 18 months by pivoting from “Commodity Tiles” to “Designer Digital Tiles” exported to the Persian Gulf markets.

۶. The “Digital Effect” and 3D Textures: The Next Frontier

The latest trend in Digital Tile Printing isn’t just color; it’s texture. This is often called “Digital Glaze” or “3D Printing.”

By using specialized printheads that can discharge larger volumes of material, factories can now print:

-

Glue for grits: For anti-slip textures.

-

Sink/Luster effects: For shiny or recessed patterns that follow the digital design perfectly.

-

Metallic finishes: Adding gold or silver accents without the need for a third firing.

This eliminates the need for expensive “molds.” Traditionally, if you wanted a textured tile, you had to buy a heavy steel mold for the press. With digital texturing, you can create a 3D effect on a flat tile, saving you thousands in tooling costs.

۷. Sustainability and the “Green” Profit

In 2026, environmental regulations are becoming stricter, even in developing industrial hubs. Digital Tile Printing is inherently greener than traditional methods:

-

Water Reduction: Digital printing is a dry process (aside from ink). There is no need to wash screens or rollers between batches, saving thousands of liters of water daily.

-

Waste Minimization: Traditional printing results in “Ink Sludge.” Digital printing uses almost 100% of the ink loaded into the system.

-

Energy Efficiency: By reducing the number of “re-fires” needed for complex designs, you significantly lower the natural gas consumption of your kilns.

۸. Overcoming Challenges in the Iranian Market

For those operating within Iran, specific challenges exist regarding Digital Tile Printing:

-

Sanctions and Parts: Sourcing genuine printheads (like Xaar, Dimatix, or Seiko) can be difficult. It is vital to work with suppliers who offer local technical support and a “safety stock” of critical components in Yazd or Tehran.

-

Ink Consistency: Imported inks can vary. Establishing a relationship with a local ink producer who uses high-quality imported pigments can provide a more stable supply chain.

Manager’s Action Step: Always keep a minimum of two spare printheads and a 1-month supply of ink in a climate-controlled storage area to avoid production halts during supply chain delays.

Conclusion: The Path Forward

Digital Tile Printing is far more than a technical upgrade; it is a strategic pivot. It allows ceramic factories to move away from the “Price War” of low-quality commodity products and into the “Value Space” of high-end, customizable, and sustainable architectural materials. By focusing on ink optimization, preventative maintenance, and high-value 3D textures, a factory can see a dramatic increase in profitability and market share.

The question for factory owners is no longer if they should go digital, but how they can optimize their digital workflow to outperform the competition. The era of the digital kiln is here—make sure your factory is leading the charge.

نظرات ۰