When one thinks of Iranian art, the mind often conjures images of magnificent mosques and historical palaces adorned with intricate, vibrant tiles. This rich legacy of Persian craftsmanship is not merely a matter of artistic genius; it is deeply rooted in the land itself. For centuries, the skilled artisans of Persia have been harnessing the earth’s bounty to create some of the world’s most breathtaking ceramic masterpieces. Today, this tradition continues on a much larger, industrial scale, powered by one of Iran’s most valuable assets: its vast and diverse mineral resources. While often overshadowed by its energy sector, Iran’s non-metallic mineral deposits are the true, albeit lesser-known, engine of its burgeoning tile and ceramic industry. This article will explore how these rich mineral veins—from the purest kaolin to the most durable feldspar—provide the essential raw materials that not only sustain Iran’s domestic market but also position the country as a key player in the global ceramic landscape.

The Core Components of Tiles and Ceramics

To understand Iran’s pivotal role, we must first look at the fundamental ingredients of ceramic production. A high-quality tile or ceramic product is a precise blend of several key minerals, each contributing a unique property to the final product’s strength, appearance, and durability.

Kaolin: The “White Gold” of Ceramics

Kaolin, a soft, white clay mineral, is arguably the most critical component. Known for its high plasticity and fine texture, it forms the body of the tile, allowing it to be shaped and molded easily. When fired at high temperatures, kaolin transforms into a rigid, non-porous material, giving the tile its strength and stability. Iran boasts significant reserves of high-purity kaolin, particularly in regions like Zanjan and Azarbaijan, which are prized for their quality and low impurity content.

Feldspar: The Flux That Binds

While kaolin provides the body, feldspar acts as the crucial “flux.” When a ceramic body is fired, feldspar melts at a lower temperature than the other minerals. This melting process fills the voids between the particles, creating a solid, vitrified mass. This vitrification is what makes the final product strong, dense, and resistant to water and stains. Iran’s rich feldspar deposits, found extensively in areas like Yazd and Kerman, are essential for creating the hard, glossy, and durable surfaces that are highly sought after in the market.

Silica: The Backbone of Durability

Silica, typically in the form of quartz, is the third major component. It is the primary glass-forming agent in the ceramic body, contributing to its mechanical strength and dimensional stability. Silica helps the tile maintain its shape during the firing process and ensures it can withstand heavy loads and abrasion. Iran’s geological makeup, with vast reserves of high-quality quartz, provides a reliable and cost-effective source of this essential mineral, underpinning the production of resilient and long-lasting ceramic products.

Other Essential Minerals: Talc, Quartzite, and More

Beyond these three, other minerals play supporting roles. Talc is often used to reduce shrinkage during firing and improve the thermal shock resistance of the final product. Quartzite and various clays are also used to fine-tune the body composition. The diverse and abundant nature of Iran’s mineral deposits means manufacturers have a wide palette of raw materials to work with, allowing for the creation of a vast range of products, from simple floor tiles to sophisticated porcelain slabs.

Iran’s Abundant Mineral Resources

Iran is a geological marvel, strategically located on a highly tectonically active belt that has endowed it with immense mineral wealth. While most of the world focuses on its oil and gas, its lesser-known, yet equally vital, industrial mineral deposits have been quietly fueling the nation’s manufacturing sector.

The Geography of Mineral Wealth

Iran’s mineral resources are spread across the country. The Alborz and Zagros mountain ranges, along with the central plateaus, are home to vast deposits of the minerals essential for ceramics. The Yazd-Kerman region is particularly famous for its high-quality feldspar, while provinces like Azarbaijan and Zanjan are major sources of kaolin and other clays. This geographic spread not only provides a consistent supply but also supports regional industrial hubs, fostering localized economic growth.

Case Study: Major Mineral Deposits for the Ceramic Industry

Consider the Meybod and Naein regions in Yazd, known for their premium feldspar. The purity and consistency of the feldspar extracted here are crucial for producing high-end tiles with excellent strength and aesthetic qualities. Similarly, the kaolin deposits in Zanjan are renowned for their low iron content, which results in whiter, more vibrant finished products, a key factor in the production of decorative tiles and sanitary ware. This combination of quality and quantity is a significant competitive advantage for Iranian manufacturers.

From Mine to Factory: The Processing Pipeline

The journey from a raw mineral in the ground to a finished tile on a factory floor is complex and requires advanced processing. This is where Iran’s investment in its industrial infrastructure becomes apparent.

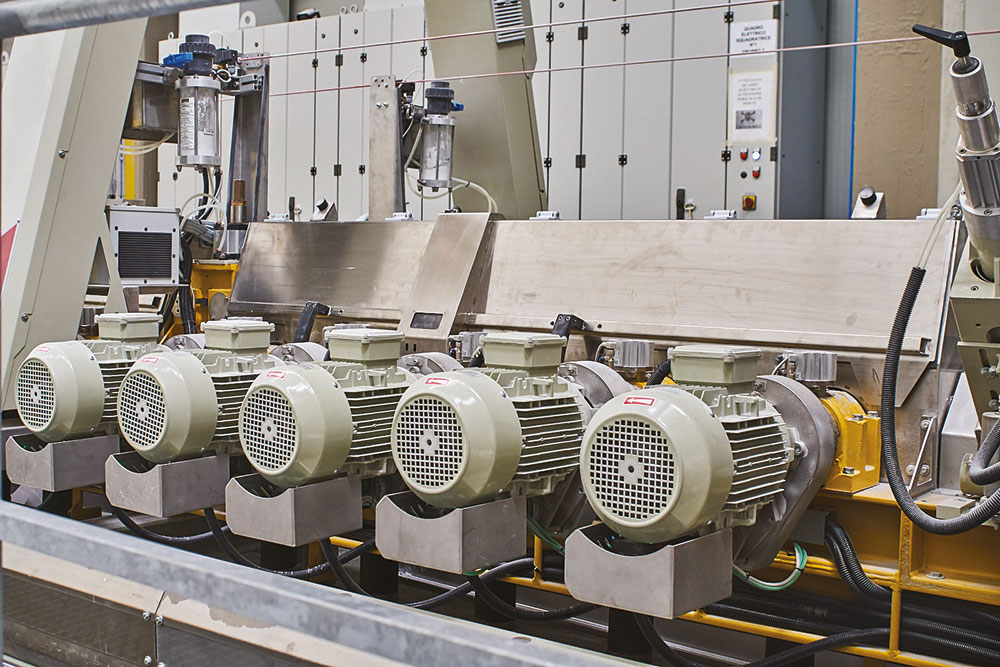

Transforming Raw Materials into Usable Powders

Mineral processing is a critical step that ensures the raw materials meet the stringent quality standards of the ceramic industry. Feldspar and quartz, for example, are crushed, ground, and purified to a fine powder. Impurities like iron oxide, which can cause discoloration, are meticulously removed. Kaolin undergoes a similar process, often with washing and filtering to improve its brightness and purity. Iranian manufacturers have increasingly adopted modern processing technologies, including ball mills and flotation units, to produce high-grade raw materials that are consistent in quality.

The Synergy Between Mining and Manufacturing

One of Iran’s strengths is the close proximity of its mineral reserves to its major ceramic manufacturing centers. This reduces transportation costs and supply chain complexities. For example, a tile factory in Yazd can source its feldspar from a mine just a few kilometers away, creating a highly efficient and cost-effective production cycle. This vertical integration—from the mine to the factory—is a key factor in the industry’s resilience and profitability, allowing Iranian companies to offer competitive prices in both domestic and international markets.

Economic Potential and Challenges

The synergy between Iran’s mineral wealth and its ceramic industry has immense economic potential, but it is not without its challenges.

Fueling Economic Growth

The tile and ceramic sector is a significant contributor to Iran’s non-oil economy. It generates thousands of jobs, from mining and processing to manufacturing and logistics. The export of Iranian tiles, particularly to neighboring countries in the Middle East, Central Asia, and even Europe, is a major source of foreign exchange. The high quality and competitive pricing of these products make them attractive to international buyers, further cementing Iran’s position as a key global supplier.

Overcoming Hurdles

Despite its strengths, the industry faces significant hurdles. International sanctions have made it difficult for Iranian companies to access modern machinery and technologies, which could improve efficiency and product quality. Furthermore, limitations on international banking and trade have complicated export logistics. However, the industry has shown remarkable resilience, adapting by focusing on domestic innovation and forging stronger trade ties with countries in the region.

Conclusion

Iran’s rich mineral resources are not just a geological curiosity; they are the bedrock of one of the country’s most vibrant and promising industries. The abundant, high-quality deposits of kaolin, feldspar, silica, and other essential minerals provide a distinct competitive advantage, enabling the production of high-quality, cost-effective tiles and ceramics. From the ancient Persian art of tile-making to a modern industrial powerhouse, Iran’s ceramic industry stands as a testament to the nation’s ability to harness its natural resources. By leveraging this mineral wealth, the industry is not only preserving a historical legacy but also building a sustainable future, one tile at a time, solidifying its role as a foundational pillar of the global ceramic landscape.

نظرات ۰