Clay is a naturally occurring material composed of fine-grained mineral particles that form a plastic mass when mixed with water. It is a key ingredient in the production of a wide range of ceramic products, including tiles, bricks, pottery, and sanitaryware. The properties of clay, such as its plasticity, firing behavior, and color, are determined by its mineralogical composition and particle size distribution.

Types of Clay

There are two main types of clay: primary and secondary

Primary clay is formed by the direct weathering of igneous or metamorphic rocks. It is typically composed of kaolinite, a clay mineral with excellent whiteness, refractoriness, and chemical resistance. Primary clays are used in the production of high-quality tiles and ceramics.

Secondary clay is formed by the transportation and deposition of primary clays. It can be found in sedimentary rocks and often contains impurities such as iron oxide, which can affect the color and properties of the fired ceramic product. Secondary clays are typically used in the production of lower-quality tiles and ceramics.

Common Clay Minerals

The most common clay minerals are kaolinite, illite, and smectite.

Kaolinite is a white, platy clay mineral with excellent plasticity and fire resistance. It is used in the production of whitewares, such as porcelain tiles and sanitaryware. Illite is a micaceous clay mineral with good strength and durability. It is used in the production of wall tiles and floor tiles.

Smectite is a swelling clay mineral with high plasticity and water absorption. It is used in the production of earthenware and stoneware.

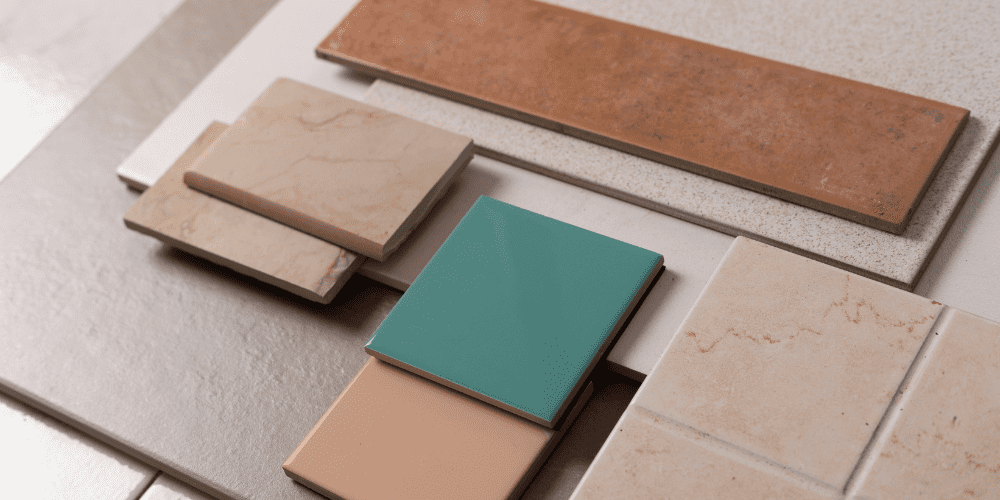

The Impact of Clay Type on Tile and Ceramic Quality

The type of clay used has a significant impact on the quality of the final tile or ceramic product. Some of the key properties that are affected by clay type include:

Strength: The strength of a tile or ceramic product is determined by the strength of the clay matrix and the bond between the clay particles. Kaolinite clays typically produce stronger products than smectite clays.

Durability: The durability of a tile or ceramic product is determined by its resistance to wear, scratching, and chemical attack. Illite clays typically produce more durable products than smectite clays.

Water absorption: The water absorption of a tile or ceramic product is a measure of its porosity. Smectite clays typically have higher water absorption than kaolinite clays.

Firing temperature: The firing temperature of a tile or ceramic product is the temperature at which it is heated to mature the clay and develop its desired properties. Kaolinite clays typically require higher firing temperatures than smectite clays.

Color: The color of a tile or ceramic product is determined by the impurities present in the clay. Iron oxide is a common impurity that can give clay a red or brown color.

The type of clay is an important factor in the production of high-quality tiles and ceramics. By understanding the properties of different clay types, manufacturers can select the right clay for their specific application.

The Application of Nanoparticles in Tile and Ceramic Production: Enhancing Strength and Water Resistance

Nanoparticles are tiny particles with dimensions ranging from 1 to 100 nanometers. They have unique properties that can be used to improve the performance of a wide range of materials, including tiles and ceramics.

Benefits of Using Nanoparticles in Tile and Ceramic Production

The incorporation of nanoparticles into tile and ceramic formulations offers several advantages:

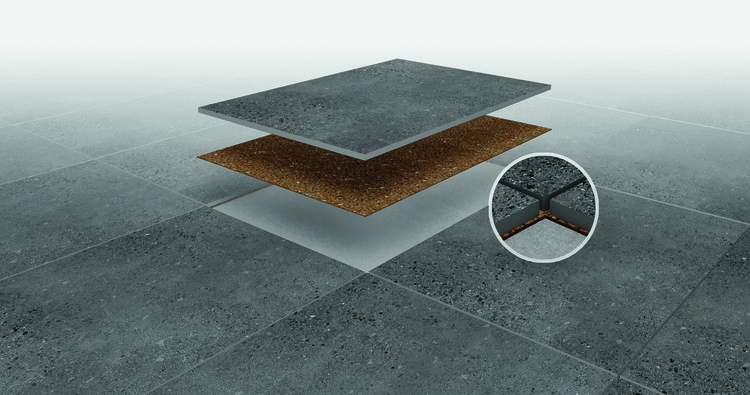

Enhanced Strength and Durability: Nanoparticles can strengthen the bond between clay particles, leading to increased strength, hardness, and resistance to cracking and chipping.

Improved Water Resistance: Nanoparticles can fill microscopic pores in the ceramic matrix, effectively reducing water absorption and enhancing the water resistance of tiles and ceramics.

Antibacterial Properties: Certain nanoparticles, such as silver nanoparticles, exhibit antibacterial properties, which can help to prevent the growth of mold and mildew on tile surfaces.

Self-cleaning Properties: Nanoparticles can be incorporated into tile formulations to create self-cleaning surfaces. These surfaces have a hydrophilic (water-loving) nature that allows water droplets to spread evenly and pick up dirt and contaminants, leading to easier cleaning.

Enhanced Coloration: Nanoparticles can be used to create vibrant and durable colors in tiles and ceramics. They can also be used to produce tiles with unique optical properties, such as iridescence or transparency.

Common Nanoparticles Used in Tile and Ceramic Production

Several types of nanoparticles are commonly used in tile and ceramic production:

Silica Nanoparticles: Silica nanoparticles are among the most widely used nanoparticles in the ceramic industry. They enhance strength, durability, and water resistance.

Titania Nanoparticles: Titania nanoparticles, also known as TiO2 nanoparticles, exhibit photocatalytic properties. They can break down organic contaminants and pollutants under UV light, making tiles self-cleaning and reducing the growth of microorganisms.

Silver Nanoparticles: Silver nanoparticles are incorporated into tiles to impart antibacterial properties, preventing the growth of mold, mildew, and bacteria.

Alumina Nanoparticles: Alumina nanoparticles enhance the strength, hardness, and scratch resistance of tiles.

Application Methods

Nanoparticles can be incorporated into tile and ceramic formulations using various methods:

Sol-Gel Method: The sol-gel method involves the preparation of a colloidal suspension of nanoparticles, which is then mixed with the clay slurry.

Co-precipitation Method: The co-precipitation method involves the simultaneous precipitation of nanoparticles and clay particles from a solution.

In situ Synthesis: In situ synthesis involves the formation of nanoparticles directly within the clay matrix during the firing process.

The incorporation of nanoparticles into tile and ceramic production offers significant benefits in terms of enhanced strength, water resistance, antibacterial properties, self-cleaning properties, and color enhancement. As research continues to explore the potential of nanoparticles in the ceramic industry, we can expect even more innovative and functional tile and ceramic products in the future.

نظرات ۰