Large-format ceramic tiles, such as those measuring 60×120 cm, have revolutionized modern architecture and interior design. Combining sleek aesthetics with exceptional durability, these tiles are increasingly favored for residential, commercial, and industrial applications. But what technological advancements enable manufacturers to produce tiles that balance strength, size, and visual appeal? This article explores the innovative processes and materials behind 60×120 cm ceramics, highlighting how cutting-edge technology harmonizes functionality and beauty.

-

Advanced Manufacturing Processes

۱.۱. Raw Material Innovation

The foundation of high-performance ceramics lies in the selection and composition of raw materials. Modern 60×120 cm tiles use a blend of premium clays, feldspar, silica, and advanced additives to enhance structural integrity. Nanotechnology is often employed to refine particle size, ensuring uniformity and reducing porosity—a critical factor in achieving both strength and a flawless surface finish.

۱.۲. High-Pressure Pressing

Large-format tiles require precise compaction to prevent warping or cracking. Hydraulic presses with pressures exceeding 400 kg/cm² are used to compress the ceramic mixture into dense, homogeneous slabs. This process minimizes air pockets and ensures consistent thickness, even across expansive 60×120 cm surfaces.

۱.۳. Digital Control Firing

Firing in kilns at temperatures up to 1,200°C (2,192°F) vitrifies the tiles, making them non-porous and highly resistant to moisture, chemicals, and abrasion. Advanced kilns with automated temperature control ensure uniform heat distribution, eliminating thermal stress and enhancing mechanical strength.

-

Strengthening Technologies

۲.۱. Reinforced Core Structures

To combat the fragility associated with large tiles, manufacturers incorporate fiberglass mesh or polymer grids during production. These reinforcements distribute stress evenly, reducing the risk of breakage during installation or use.

۲.۲. Edge and Surface Treatments

Precision-cut edges and anti-slip coatings (e.g., R11-rated surfaces for outdoor use) improve durability. Additionally, glazing techniques like digital inkjet printing not only enhance aesthetics but also create protective layers against scratches and stains.

-

Aesthetic Innovations

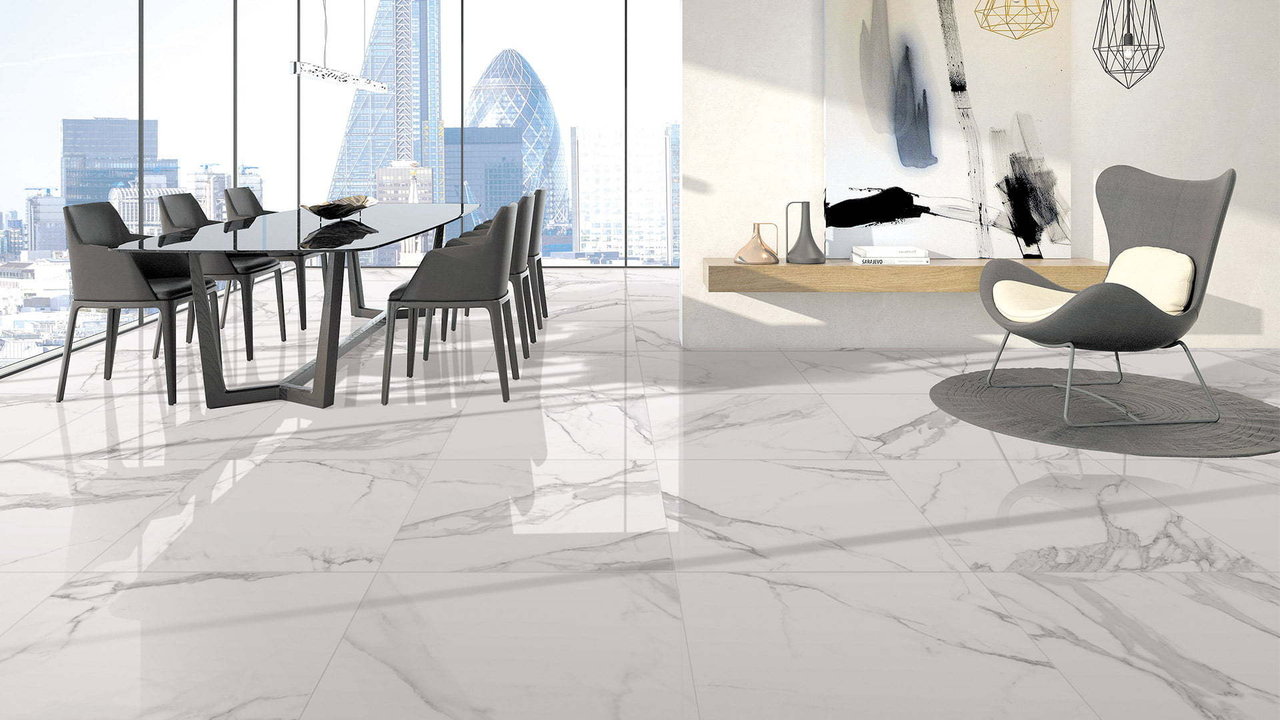

۳.۱. Digital Printing Technology

High-resolution digital inkjet printers allow for hyper-realistic replication of natural materials like marble, wood, and stone. This technology enables designers to achieve intricate patterns, textures, and color gradients on 60×120 cm tiles, mimicking premium materials at a fraction of the cost.

۳.۲. Texture and Finish Variations

From polished surfaces for a sleek look to matte or textured finishes for slip resistance, advanced embossing and glazing techniques cater to diverse design needs. For example, 3D embossed tiles add tactile depth, while lappato finishes blend gloss and matte effects for visual intrigue.

-

Sustainability and Efficiency

Modern production lines prioritize sustainability:

– Water recycling systems reduce waste during manufacturing.

– Energy-efficient kilns lower carbon footprints.

– Thin-profile tiles (as slim as 5.5 mm) minimize raw material usage without compromising strength.

-

Applications and Benefits

۶۰×۱۲۰ cm ceramics excel in:

– Commercial spaces (airports, hotels) due to high foot traffic resistance.

– Residential interiors (kitchens, bathrooms) for seamless, minimalist designs.

– Outdoor areas (patios, facades) thanks to weather-resistant coatings.

-

Challenges and Solutions

– Installation Complexity: Specialized adhesives and laser-guided cutting tools ensure precise placement.

– Transportation Risks: Reinforced packaging and modular shipping crates prevent damage.

-

Case Studies

– Atlas Concorde’s Marvel Pro Series: Combines 60×120 cm tiles with antimicrobial coatings for healthcare facilities.

– Florim’s Magnum Oversize Collection: Uses recycled materials to create eco-friendly, large-format ceramics.

Conclusion

The production of 60×120 cm ceramic tiles exemplifies how technological innovation bridges the gap between strength and beauty. By integrating advanced materials, precision engineering, and sustainable practices, manufacturers deliver tiles that meet the demands of modern design while ensuring longevity. As technology evolves, expect even smarter ceramics—embedded with sensors or self-healing coatings—to redefine the boundaries of architectural possibilities.

نظرات ۰