Glaze and Its Types in the Tile and Ceramic Industry

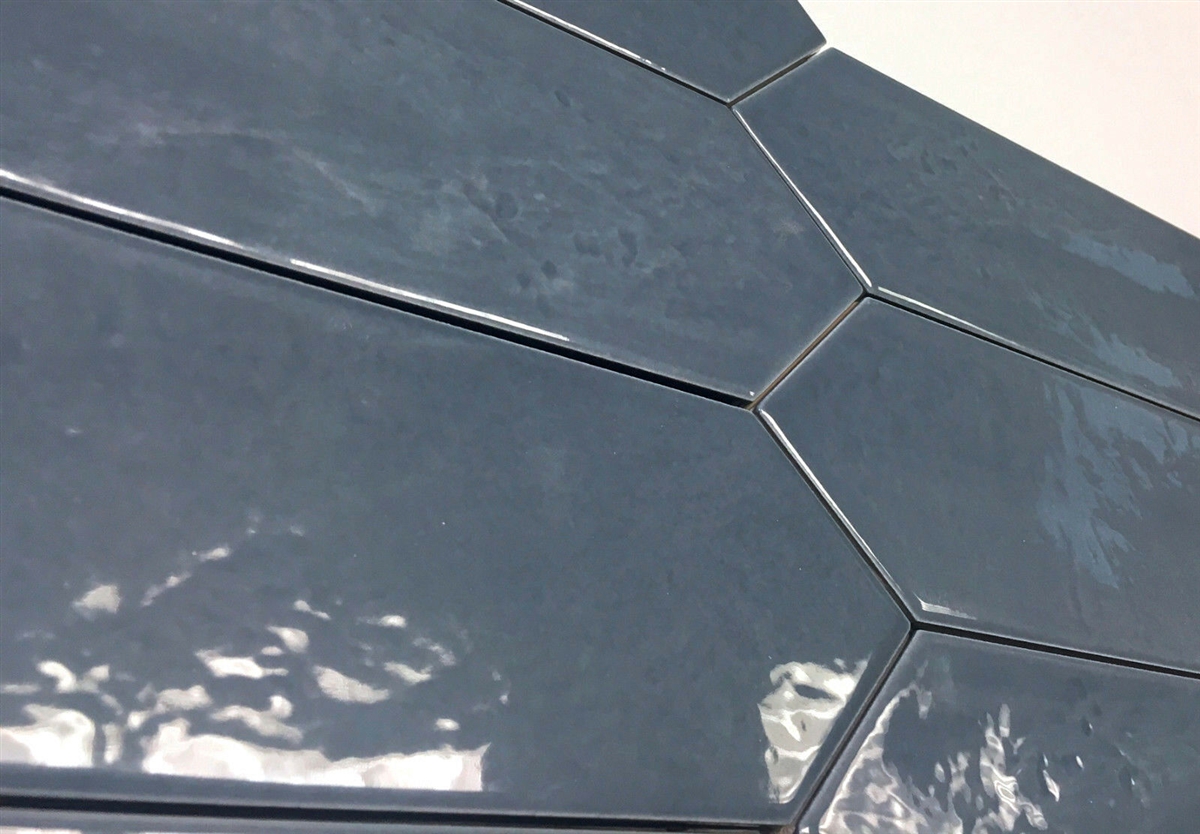

Glaze is a glass-like coating applied to the surface of tiles and ceramics. Essentially, it originates from a raw, dry material that, after grinding, is mixed with water to form a thin slurry. This slurry is then applied to the ceramic or tile body using various methods and fired in a kiln at a specific temperature. This process enhances the product’s aesthetic appeal, luster, and durability.

While glaze itself is not an adhesive, it penetrates the clay body upon contact. When subjected to a specific temperature, it forms a coating on the tile’s surface.

Types of Tile and Ceramic Glazes

The color and type of glaze depend on its formula and constituent materials. By varying the proportions of these components, new colors and glazes can be created.

In the tile and ceramic industry, there are various glaze application methods:

- Colorless Glaze: Used for coating delicate imitation porcelain, it is transparent and made from a mixture of calcium, silica, and white clay.

- Colored Glaze: The most common type, colored glazes are obtained using metal oxides. For example, copper oxide (Cu2O) produces blue, iron oxide (FeO) produces yellow, and chromium oxide (Cr2O3) produces green.

- Opaque Glaze: Used for coating ordinary imitation porcelain, it is made from a mixture of SnO2, PbO, SiO2, Pb3O4, salt, and sodium carbonate. After melting, cooling, and powdering, it is mixed with water to form a milky bath and the glazed object is immersed in it.

- Textured Glaze: This type of glaze contains particles of decorative stones and silica, creating a rough surface. Due to its high friction, it is suitable for use as floor tiles.

Applications of Glaze in the Tile and Ceramic Industry

In the tile and ceramic industry, glaze types are categorized based on the amount of glaze applied to the product:

- Double-fired tiles: Glazed after the initial firing.

- Single-fired wall tiles: Glazed before the final firing.

- Single-fired floor tiles: Glazed before the final firing.

- Porcelain tiles: Can be either single or double fired, depending on the specific product.

Benefits of Glaze

- Smooth surface

- Enhanced aesthetics

- Increased resistance to chemicals

- Reduced water absorption

- Improved strength

How Glaze is Applied to Tiles and Ceramics

After the biscuit (unglazed tile) is fired, glaze is applied and the tile is fired again to enhance its durability.

Additional Notes:

- Biscuit: The initial fired state of a ceramic piece, before the glaze is applied.

- Slurry: A watery mixture of a solid substance, in this case, the ground glaze materials.

- Firing: The process of heating ceramic pieces in a kiln to fuse the materials together.

- Metal oxides: Compounds formed when oxygen combines with a metal. These are commonly used to color glazes.

Would you like me to elaborate on any specific part of the text or provide more information on glaze and its applications?

Possible areas for further exploration:

- The chemical composition of different glazes and how they affect color and properties.

- The history of glaze and its development.

- Different glaze application techniques (e.g., dipping, spraying, brushing).

- The role of temperature in the glaze firing process.

- The environmental impact of glaze materials and production processes.

Tiles vs. Ceramics: Key Differences

While tiles and ceramics are often used interchangeably, they have distinct characteristics.

Tiles are artificial stone pieces with varying lengths and widths, but a relatively consistent thickness of a few millimeters. One side is porous and serves as the base, while the other is glazed and has a smooth, glossy finish. The term “tile” is derived from the Latin word “tegula,” meaning “roof tile,” and refers to any covering material for buildings.

Ceramics are a broader category encompassing all non-metallic, inorganic solids. They are created by heating a mixture of clay and feldspar at high temperatures, resulting in a hard, non-porous material. Ceramics are extremely durable and resistant to chemicals. The word “ceramic” originates from the Greek word “keramos,” meaning “pottery” or “something burned.”

Key Differences:

- Strength: Ceramics are generally stronger and denser than tiles, making them more suitable for high-traffic areas like floors. Tiles, being more delicate, are often used on walls.

- Water Absorption: Tiles typically have a higher water absorption rate compared to ceramics. This makes tiles easier to adhere to walls but less suitable for areas exposed to excessive moisture.

- Appearance: While there can be significant overlap in appearance, ceramics often have a more refined and uniform look due to the higher firing temperatures and denser material.

- Applications: Tiles are primarily used for wall coverings, while ceramics find applications in both wall and floor coverings, as well as in specialized products like tableware and sanitaryware.

In summary, while tiles and ceramics share similarities in their manufacturing process, their distinct properties make them suitable for different applications. Tiles are often chosen for their aesthetic appeal and ease of installation on walls, while ceramics offer superior durability and resistance to wear and tear, making them ideal for floors and other demanding environments.

قیمت های موجود در سایت تاریخ بروزرسانی آن ها ذکر شده و قیمت نهایی محصولات نمی باشند. لطفا جهت ثبت سفارش و استعلام قیمت بروز با کارشناسان ما در ارتباط باشید.

(035-3357)